-

Shenzhen ,China.

Deeply Engaged in One-Stop PCBA Services, JCPCB Makes Production More Efficient and Delivery More Worry-Free

Advanced PCB Manufacturing Facilities

Cutting-edge technology & skilled teams driving ISO-certified quality and innovation.

01.

Best Value

The Factory with the Greatest Cost Performance

02.

Fast delivery

As fast as 8 hours

03.

One-on-one service

Attentive service throughout! Custom PCB solutions, tech team's full support, rapid after - sales. We'll power your products to the lead.

Why Choose Us

Reliable PCB Assembly Manufacturer Since 2015 | 5,000+ Clients Served

✓ Dedicated Account Managers

Personalized support from order to delivery

✓ Fast Quotes

8-hour PCB quotes | 2-day PCBA estimates

✓ 10,000m² Certified Facilities

ISO 9001, IATF 16949, IPC-A-610 Class 2/3 compliant

✓ UL Certified & RoHS Compliant

Lead-free soldering | ISO 13485 & IPC/WHMA-A-620 certified

✓ Trusted Components

Sourced from authorized distributors: Mouser, Digi-Key, Future Electronics

✓ Full-Service Solutions

PCB Fabrication | Assembly | Wire Harness | Component Sourcing | Testing

End-to-end manufacturing with premium quality and global standards.

13 years of manufacturing experience

12,000 square meters of modern plant

500 employees with100 automated machines

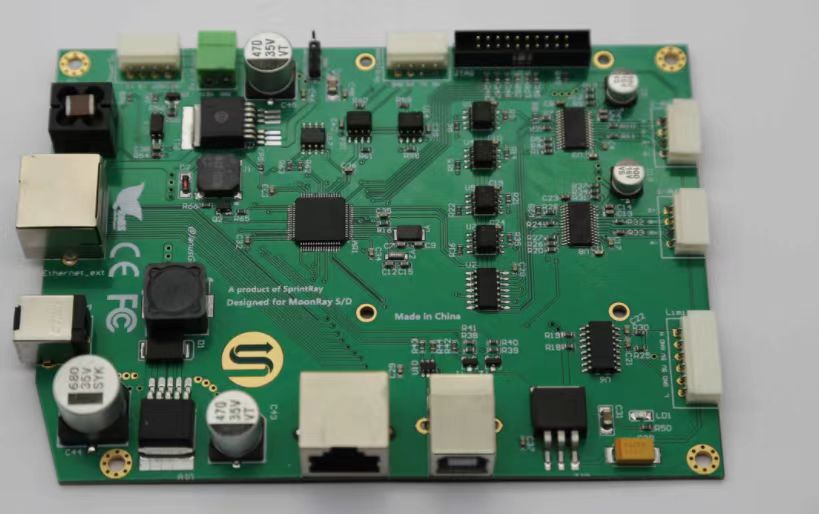

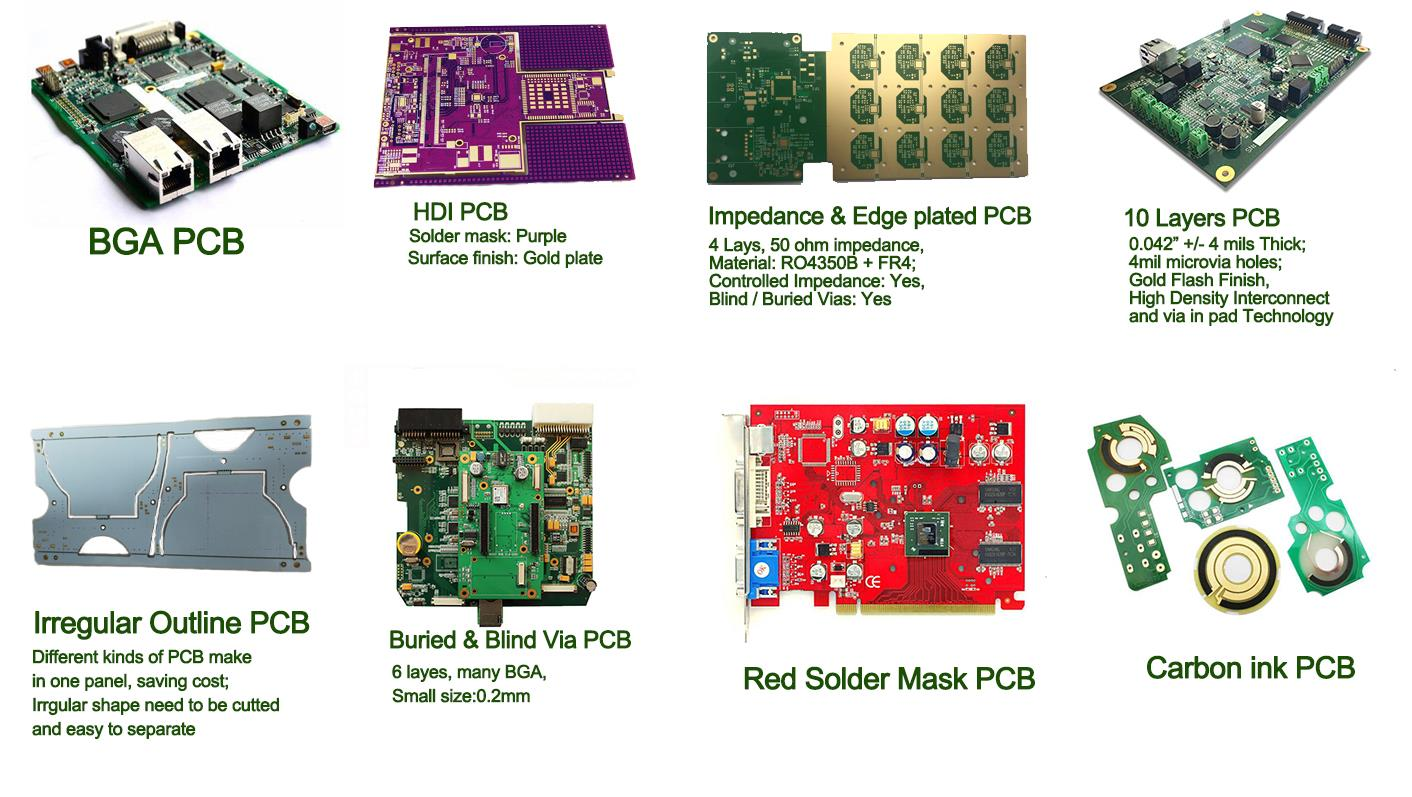

Products We Are Proud Of

These products reflect our strict standards for quality and user experience. Each product is carefully designed to meet the needs and expectations of our customers.

What Our Client’s Say

Frequently Asked Questions

The minimum thickness of the PCB is 0.2mm.

The minimum mechanical drilling size is 0.15mm, and the minimum laser drilling size is 0.1mm.

The fastest delivery can be made within 24 hours.

Support 2-4 HDI boards with buried/blind vias (±50μm accuracy). Backdrilling stub length ≤0.5mm.

Our high-precision SMT machines (e.g., FUJI NXT, Yamaha YSM) support 01005 components with ±50μm placement accuracy, suitable for medical/aerospace applications.

Our high-precision SMT machines (e.g., FUJI NXT, Yamaha YSM) support 01005 components with ±50μm placement accuracy, suitable for medical/aerospace applications.

We support 0.3mm pitch BGA/QFN with SPI/AOI inspection for quality assurance. Underfill and conformal coating services are available for reliability enhancement.

ESD bags + foam packaging with “Fragile”/”Moisture Proof” labels. Door-to-door international logistics via DHL/FedEx, including customs clearance.

One-stop kitting service with authorized distributors (Avnet, Mouser). We assist in obsolete inventory management (storage, resale) to reduce costs.